INTEGRAL HOT-DIP GALVANIZED FRAMES & TUBES

Depending on the dryers series we provide the full hot – dip galvanization of both chassis and frames as a standard or as an optional.

This hot-galvanized frame is an addition to all the other components that we already as standard supply with hot galvanizing (pipe and basin of the loading screw, pipes of the middle vertical screw and others).

The complete galvanization process is done with a full immersion of the frame in a bath of molten zinc at a temperature of around 840 °F (449 °C) giving 1mm more of thickness to all the steel used.

The galvanizing protects steel by acting as a barrier between steel and the atmosphere, keeping your machine protected also in the most extreme conditions.

This Pedrotti dryers frame is completely galvanized, not just assembled with several galvanized parts. This means true quality and duration in time.

We use for our augers tubes, a Carbon steel C430 (S275J10 EN 10025-2:2004), 4 mm of thickness before being fully galvanized. By total galvanization, we give an additional thickness of 1 mm and therefore a longer life.

U-PROFILES FRAMES STRENGTH

All our frames are designed and shaped in a way that grants the maximum strenght to all our dryers models.

Manifacturing with U type calendered steel , infact, consents the longest duration possible for steel frames.

HARDOX REINFORCED AUGERS

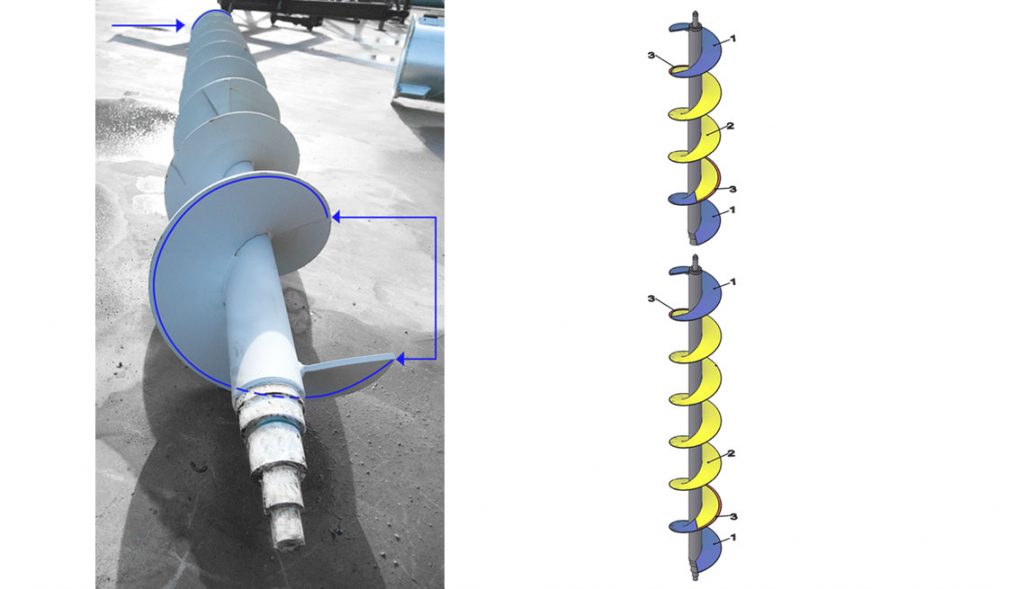

Instead of increasing the thickness of the central augers, which would increase also the required power of the motor and the electricity consumptions, we prefer to use more hard and noble metals. Pedrotti dryers have central augers with three different sectors:

- Hardox steel segment, thickness 8 mm, 425 min. / 475 max. HBW (Brinell Hardness ).

- Standard carbon steel thickness of the spiral foot is 12 mm and thickness of the spiral ridge is 6 mm.

- Weld bead on the ridge for one turn around the auger.