PEDROTTI HEAT EXCHANGER

Today, indirect fire (synonym for ORGANIC) drying process is still not compulsory, except in some countries and only for some products.

However, it is undeniable that in recent years market operators – farmers, traders, food processing industries – have became more and more sensitive and pay more and more attention on this aspect of the drying grain process.

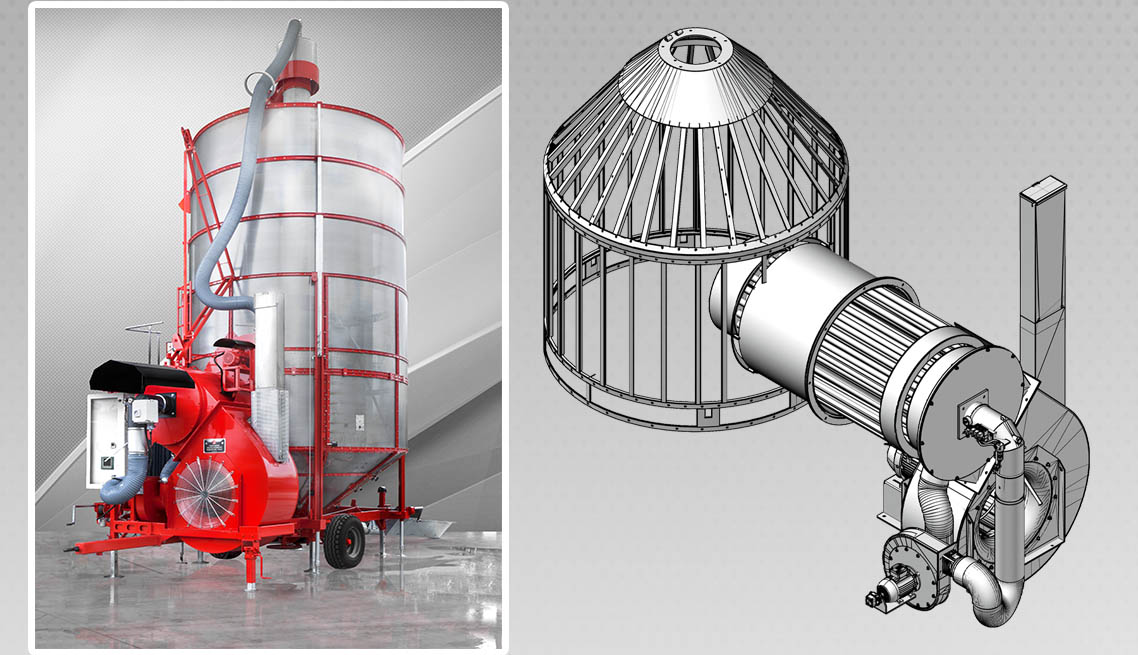

As an answer to this major sensitivity, Pedrotti offers the latest generation of heat exchanger COMPACT series.

Indirect fire

systems are still today

the best way

to obtain a

suitable organic product for human

consumption.

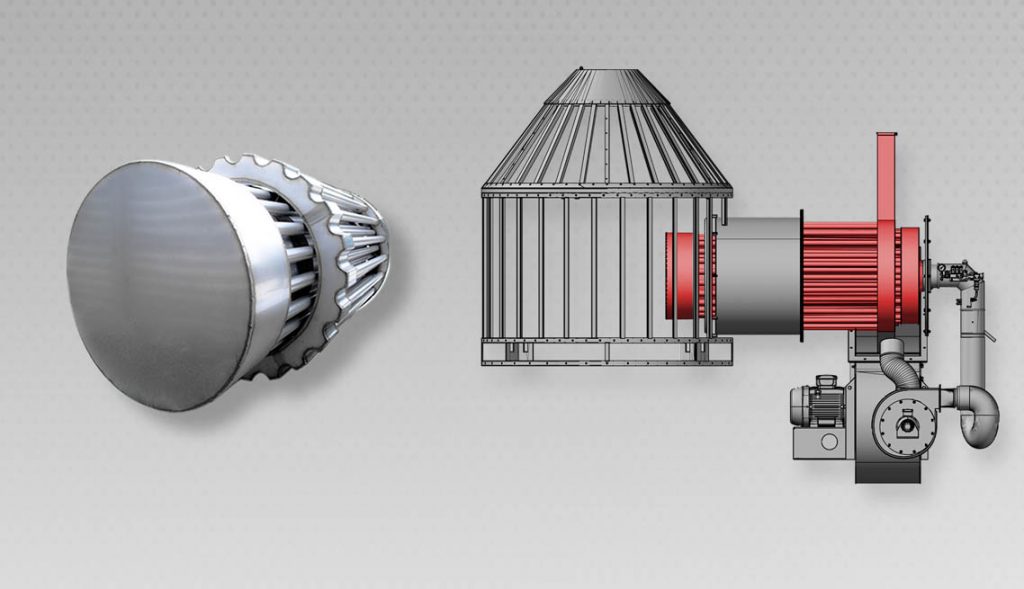

The modern design, the compact structure, the employment of precious materials (three different kinds of steel) in order to optimize the heat performance, permit to overcome all traditional obstacles that can occurs with an heat exchanger (high extra charge; high fuel consumption; low limit of the temperature for working).

As a result the price is much more competitive and the heat performance is never under the 90%. The “Compact” exchanger is installed in the inside of the dryer and it does not increase the usual dimensions of the machine. The working temperature can reach 90°C/100°C beyond the room-temperature.

The compact Pedrotti heat exchanger is installed in the inside of the dryer and it does not increase the usual dimensions of the machine.