ACCIDENT PREVENTION FOR THE OPERATORS

Each organ that moves is protected against any possible contact with the persons that stand in the nearby of the machine.

A specific range of cases that have been studied accurately provides complete protection. Furthermore, they are easy to remove and to put back when the machine has to be controlled or if some maintenance has to be done.

However, the most important and frequent maintenance works, such as greasing, can be done without removing any protections and even while the machine is still working.

The SIEMENS LOGO! TD is part of our standard dryers features. Ruled by a PLC, it controls the burner along with all the moving parts and grants a perfect functioning of the machine. It also provides an alarm list and warning messages, in order know that your dryers are working properly.

As it is a very dangerous operation, particular attention has to be paid to prevent any access inside the machine that can occur through the inspection and access door. An electric system that controls the closing provides for the automatic stop of the machine whether the protection of the access door had been removed (electric machines).

For those machines activated through PTO, the removal of the protection system would be followed immediately by an acoustic alarm.

In general, the machine is made in conformance with the European law EEC 42/2006, currently in force, concerning the accident prevention. We have the same regard to the prevention also for what concerns the electric system and the control panel.

FIRE ACCIDENT PREVENTION

The dryer is a machine that has a heat generator that is the heat produced by the flame of the burner. The presence of a flame can obviously involve the risk of fire accident.

We operate all the solutions aimed to prevent that such an incident occurs. Conditions that potentially could lead to critical situations could be:

A) – Stop or sensible decrease of the air flow

B) – Stop or a significant decrease in the grain cycling

C) – Too high level of the drying air temperature

Our standard electronic safety systems that can prevent all these eventualities:

- Stop or sensible decrease of the air flow. This is the most dangerous eventuality. In this case, it is necessary to make a distinction between the electric traction machines and the cardan traction machines:

- On electric machines: The switching on and the functioning of the burner are connected with the functioning of the motor that drives the ventilator. If the motor is not working or if it switches off for any reason, the burner will be inert. It cannot be possible to switch it on if you do not switch on the motor of the ventilator before.

- On cardan traction machines (PTO) Cardan traction machines have their generator. Its main function is that of providing electric energy to the burner. The generator is activated by a referral system belt that connects the pulley to the shaft of the generator to the traction pulley installed on the shaft of the ventilator.The generator works exclusively while the ventilator is working, even if it rotates at a wrong number of revolutions.A decrease of the running speed of the ventilator – for instance due to a loss of revolutions of the tractor’s engine, or if the fan stops because the transmission belt connected to the ventilator shaft breaks – leads to the automatic stop of the electricity that supplies the burner, provoking it’s switching off.Another expedient is applied to the mobile covering that obstructs the entrance of the ventilator during the loading and unloading stages, which do not need the usage of the ventilator. In order to prevent the wrong startup of the burner during these operations (when the ventilator is obstructed), the system of mobile covering impedes, when it is obstructed, the switching on of the burner, thanks to its electric control system.

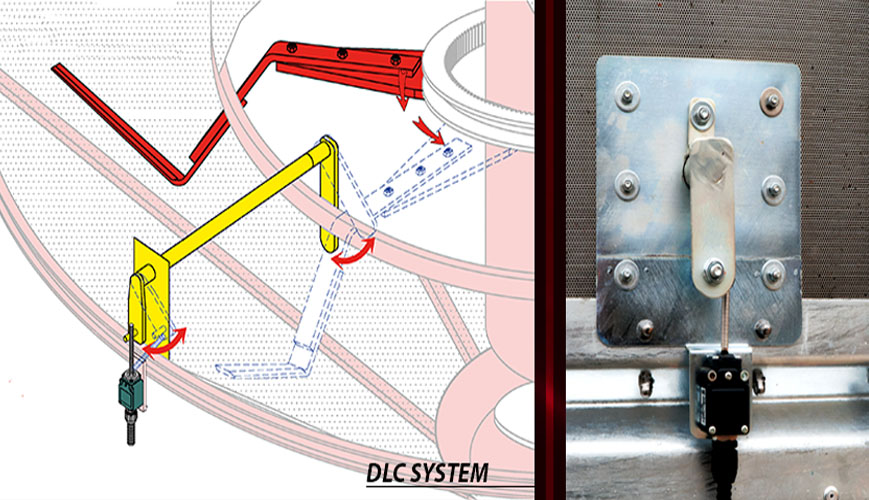

- Stop or significant decrease in the grain cycling. The batch cycle of the grain inside the dryer is continuous, and the central screw conveyer’s movement guarantees it.The central screw conveyor is activated through a system belt. The batch cycle of the grain stops if the transmission belts break or if they come loose. These events can occur especially if the machine is old.If this happens, the grain exposed to the warm air flow remains always the same, and there is the risk of an overheating if the operator does not notice in time what is happening. In the long period (hours) the overheating can provoke a fire and, in the case of some kinds of products (such as colza and sunflower) the fire can break out in a very short time. In order to prevent this risk the dryer is equipped with a permanent Driving Line Control (DLC), a simple but efficient mix of mechanical units matched with an electronic board. It constantly senses the regular movement of the central auger and the agitators inside the machine, checking the correct flow of the grains. A pendulum is moved by each passage of the three agitator arms and sends a consense signal to an electronic device. As long as the arms are in regular movement, the burner will continue working, while if it stops for any reason, the flames will immediately turn off. With this system, added to the overheating safety, you can be sure to have always your dryer under total safe control.

- Too high level of the drying air temperature: The operator on a thermostatic instrument arranges the limit of the level of the drying air’s temperature. When the temperature reaches the limit, the instrument intervenes on the system of modulation of the burner’s flame so that it alternates the low and high flame.A bad functioning of the thermostatic instrument or in the burner’s modulation system could let the burner over a continuous high flame situation, causing the overheating.The same problem could take place if the cereal has a high humidity percentage or if it is particularly dirty (two conditions that often can occur at the same time). In this circumstance, even if the burner is over a low flame, this can be sufficient to push the temperature over the limit established by the operator. We prevent such risk on all our dryers using an electronic safety. If the temperature raises few degrees over the limit, the system intervenes and switches the burner off. The switching off is immediately followed by a lit emergency alarm and even if the temperature goes down, the system does not allow the automatic switching on of the burner.

Our standard safety system grants protection to the machine, the persons involved in the work, and the environment surrounding the machine, such as storages, farms and other buildings or machineries.