PEDROTTI PULLEYS SYSTEMS

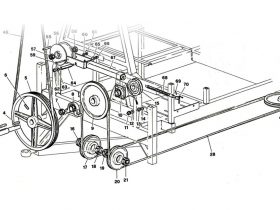

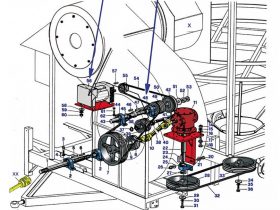

Since the early Eighties, it became clear to us that the chain systems and the direct connections to the central auger with shafts and square gear reducers were too stiff systems.

Grain drying is a tough job, and it requires strength, control and more than everything, flexibility. When the moisture level is high the weight of the crops increases and the stress on the mechanical junctions between the engine and the auger can become unbearable by stiff connections, subjected to constant wearing through time.

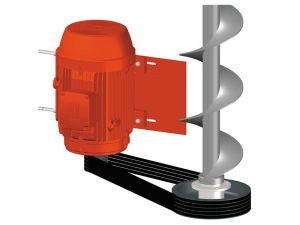

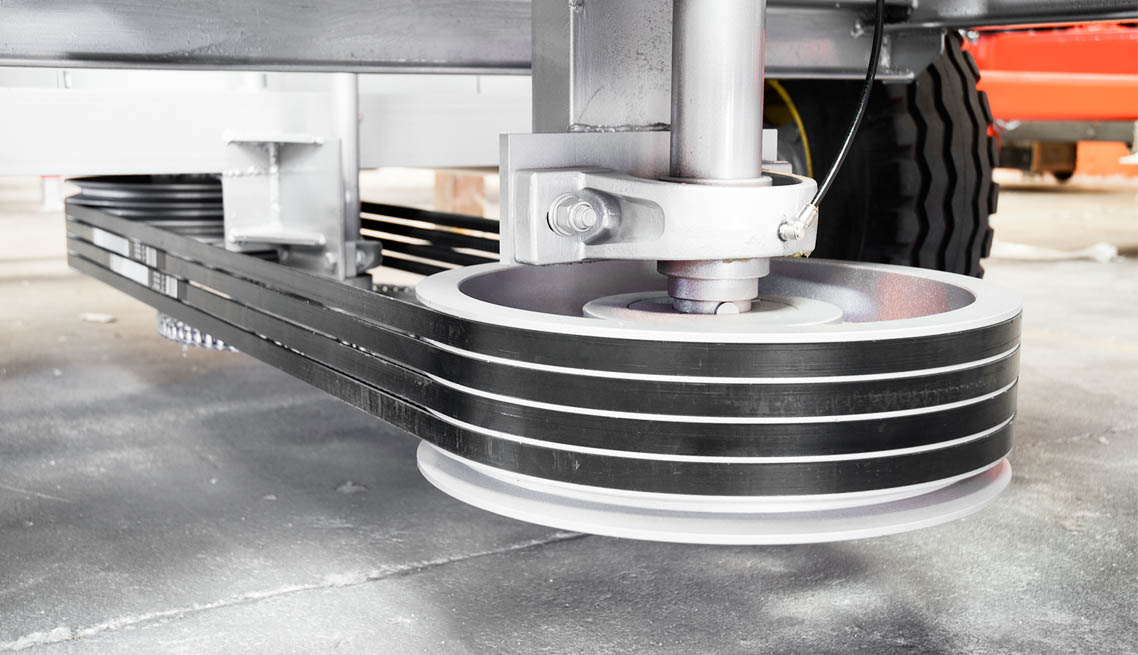

Belts are different, in the cases of massive stress on the augers they just slip on the pulleys and continue working anyway. In the case of giant machines, dealing with enormous crop weights, we give as an optional an external pulley reducer, which avoids even the slightest slipping of the belts.

Instead, when a bottom square gear reducer or a ring gear breaks up on a grain dryer, usually the dryer is full and fixing it is very difficult due to its positioning and its mechanical connections; more than this is a very expensive procedure

While changing a belt is as fast as you can imagine, grants a huge saving in costs, avoids delays during the drying season and prolongs the life of the dryers up to 35 years or even more.

That’s why we chose pulleys for our dryers so many years ago. But even nowadays this remains a premium level system, and we are proud to be the only manufacturer able to run it on both electric and PTO batch grain dryers.