HEAT-ENERGY SAVING

It is the most important part of the required energy: about the 95% of the total.

It is produced by the combustion of the selected fuel (diesel or gas). Its aim is to heat the air flow which ensures the evaporation of the exceeding moisture contained in the grain.

The consumption of fuel per ton of grain, gas oil, methane or bottled gas, depends on the total quantity of water that you have to extract and, therefore, on the initial and final humidity percentage of the grain.

However, many other elements are relevant and affect the final level of consumption significantly.

These elements are

- Outside temperature level

- Relative air humidity percentage

- Grain’s maturity degree

- Grain’s cleanliness level

When we indicate the specific consumption of the fuel – that is to say the quantity of fuel per ton of wet grain – we refer to the following general conditions:

- Outside temperature: Not lower than 15 °C

- Relative air humidity percentage: Not higher than 70%.

- Grain’s maturity: Perfect and complete

- Cleanliness: Impurity level not higher than 3%.

Often, in addition to the consumption of fuel per ton, it is common to indicate also the quantity of fuel you need to evaporate one kg of water.

The chart below shows the values mentioned above. Remember that these are average values that can be altered significantly by conditions different from those previously described.

| Humidity % Initial/Fina | Total Kg of water to evaporate per Ton of humid grain | Litre of gas oil per Ton Kcal/kg of H2O evaporated |

|---|---|---|

| 28% – 14% | 163 | 15l/Ton. – 800 Kcal/Kg H2o |

| 24% – 14% | 116 | 12l./Ton – 880 Kcal/Kg H2o |

| 19% – 14% | 58 | 7l./Ton – 1.050 Kcal/Kg H2o |

It is important to note that at the decreasing of the initial humidity, the specific consumption increases, even if the absolute consumption is going to be lower.

It can be explained by the fact that the resistance of the grain to the release of the internal humidity is more and more strong while the humidity is decreasing.

For the same reason, if the drying process ended at a lower level, for instance at 12%, the specific consumption would be certainly higher than the value of the chart.

The fuel consumption can be optimized – reduced at its physiological minimum – using technical solutions that permit to have the highest efficiency.

For these reasons Pedrotti dryers have:

-

- a very efficient boiler (immediately hot, immediately cold);

- a system of thermal insulation with a cold air flow that passes through the gap between the inner and external side of the funnel surrounding the boiler;

this system permits also to remove the heat loss through the external walls of the boiler.

The heat loss that you can have through the external walls of the dryer has been reduced to the minimum – as a result of many tests – thanks to the accurate dimensioning of the thickness of the column of grain around the warm air expansion’s room. With a too small thickness, the air will go out when it is still too hot and not yet saturated. On the other hand, with a too big thickness, the air would be saturated before coming out from the dryer. As a consequence, the heated air would release the humidity inside the dryer.

Finally, the machine has a gravity cleaner that expels all the heavy impurities while the dryer is working. So, the increase of consumption due to the presence of solid impurities can reduce to the minimum. Furthermore, you can fit the machine with a dust extractor cleaner (see “Options menu”) that cleans the lightest and more volatile impurities from wet grain vigorously during the very first hour of the process. What is removed from the crop do not need to be dried. As a result, you will increase the final value of the global consumption and get a better quality of the dried crop.

Even if it the dust extractor cleaner remains an optional feature, most of the machines are equipped with this accessory in confirmation of its usefulness.

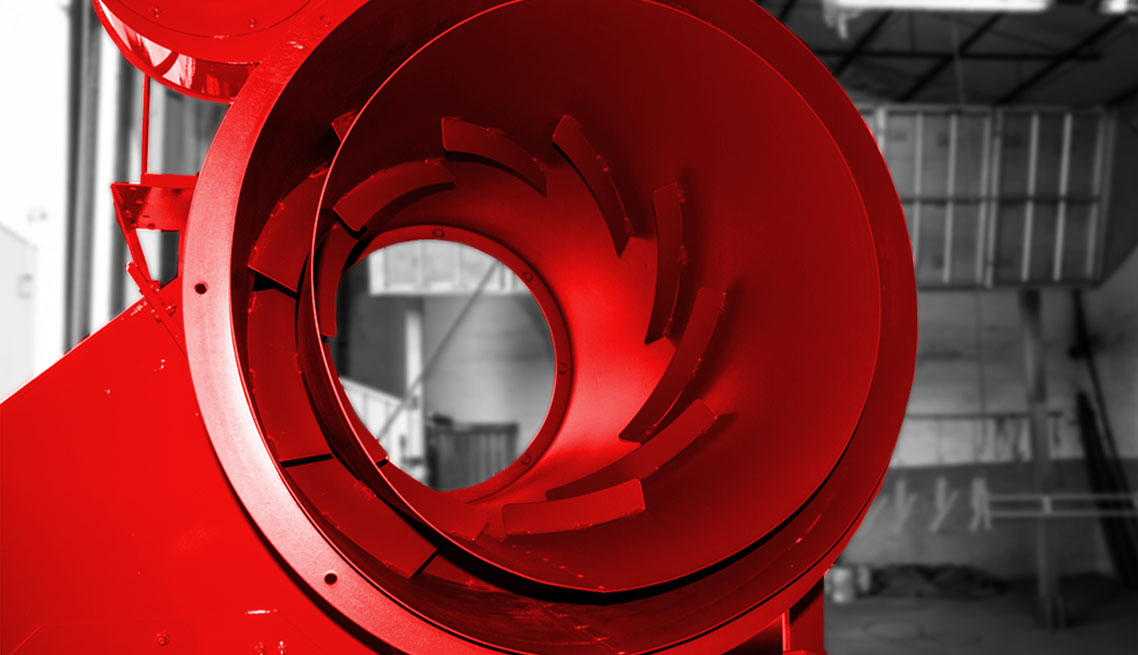

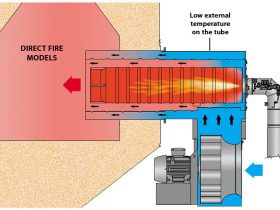

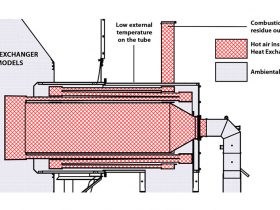

COMBUSTION CHAMBER FUNNELS

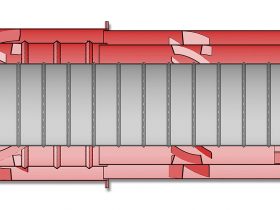

We use special designed combustion chamber funnels to ensure that each calorie produced by the burners goes directly inside the crop, without any heat loss. The air coming from the fan divides in two different flowlines, producing a natural separation of each internal chamber funnels, reducing the thermal shocks exposition and granting a longer life to the steel used.

The internal flaps consent a perfect flowline inside the funnel, allowing a homogeneous distribution of the air and a better heat flux. Furthermore the 4 different internal spirals increase the air speed, giving to the fan better performances and lower counterpressure.

Since the 1985 both in the heat exchanger and direct fire grain dryer models our choice is to use the natural insulation of the chamber funnels.

In this way we are able to guarantee an important safety around the machine, letting the user to touch the external part of the funnel with bare hands without any burns.

The heat flowline in both cases remains internal, and there is practically no dispersion to the outside. And no heat dispersion means safety but also an important fuel saving.

MECHANICAL-ENERGY SAVING

It is the energy required by the machine in order to move its mechanical components, that is to say: ventilator; loading screw conveyer; cycling and unloading screw conveyer; grain mixing system.

For those machines that work with cardan transmissions the energy comes from the PTO of a tractor. For those machines that work with electric traction, the energy comes from the motor-kit installed on the machine.

The consumption of mechanical energy depends on the time the machine needs to complete one work-cycle.

Some stages of the process, such as loading, cooling and unloading, have always the same length. On the contrary, the stage of drying is directly connected with the initial humidity percentage of the grain and with the final humidity percentage you want to achieve.

In order to reduce at minimum the level of the energy that you need, PEDROTTI Driers take all the measures that permit to reduce the friction in the transmission: high quality bearing (SKF); pulleys with a diameter that assures the best efficiency of the transmission; high quality belts.

Long since, we have abandoned the idea of using a single electric motor on the electric machines (still in use on the machines of our competitors). We have preferred to install a specific motor for each mechanical function of the machine (upload, batch cycle, ventilation). This solution is more expensive to build, but it improves the quality of the machine. As a result the machine’s mechanism and its maintenance are simpler and the machine absorbs less power because the motors of each stage of the process work one at a time.

In order to optimize the level of absorbed energy, we want to remember you that:

- All electric motors are at least 20% oversized with respect to the maximum load they can sustain. This solution impedes any overheating and improves the machine’s performance.

- We only use IE3 high efficiency motors whose employment is moreover compulsory since 2015 in accordance with the European law CE 640/2009.

The specific consumption of energy (energy per ton) – expressed with the quantity of gas oil required by the tractor or by the quantity of Kw absorbed by the electric machines – is approximately the following:

It is the energy required by the machine to move its mechanical components, that is to say: ventilator; loading screw conveyor; cycling and unloading screw conveyor; grain mixing system.

For those machines that work with shaft transmissions, the energy comes from the PTO of a tractor. For those machines that work with electric traction, the energy comes from the motor-kit installed on the machine.

The consumption of mechanical energy depends on the time the machine needs to complete one work-cycle.

Some stages of the process, such as loading and unloading, always have the same length. On the contrary, the duration of the drying stage is directly connected with the initial humidity percentage of the grain and with the final humidity percentage you want to achieve; The cooling time instead largely depends from the outer temperature.

To reduce at minimum the level of the energy that you need, Pedrotti Dryers take all the measures that permit to reduce the friction in the transmission: high-quality bearing (SKF); pulleys with a diameter that assures the best efficiency of the transmission; high-quality belts.

Since we have abandoned the idea of using a single electric motor on the electric machines, we preferred to install a specific motor for each mechanical function of the machine (upload, batch cycle, ventilation). This solution is more expensive to build, but it improves the quality of the machine dramatically. As a result, the machine’s mechanism and its maintenance are simpler, and the machine absorbs less power because the motors of each stage of the process work one at a time.

To optimize the level of absorbed energy, we want to remember you that:

- All electric motors are at least 20% oversized concerning the maximum load they can sustain. This solution prevents any overheating and improves the machine’s performance.

- We only use IE3 high-efficiency motors whose employment is moreover compulsory since 2015 in accordance with the European law CE 640/2009.

The specific consumption of energy (energy per ton.) – expressed with the quantity of gas oil required by the tractor or by the quantity of Kw absorbed by the electric machines – is approximately the following:

| Reduction humidity’s points | PTO Machines litre/ton | Electric Machines Kw/Ton |

|---|---|---|

| 15% | 2,0 | 7,5 |

| 10% | 1,5 | 5,5 |

| 5% | 1,0 | 4,0 |