TOTAL AUTOMATION

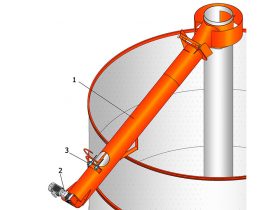

The electric version of Pedrotti Dryers can reach a high level of complete automation choosing this optional feature.

It includes the automatic stop at the end of the batch cycle; the start of the unloading through a motorized flap and the restarting of the new load once completed the unloading of the product. The system allows in an easy and very understandable way even to set the definitive stopping of the machine after a pre-selected number of batches.

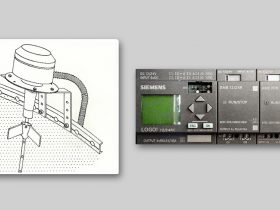

The control panel and the settings can be controlled easily through a modern PLC unit, whose display is perfectly integrated into the control panel of the machine. All the internal PLC is SIEMENS branded: trustful and long-lasting components as they always have been in our long-term cooperation.

FULL AUTOMATION OF THE BATCH CYCLE with SIEMENS TD or SIEMENS KTP 700

HOW THE AUTOMATIC PEDROTTI DRYER WORKS

Our Automatic optional consents to use the machine in a continuous drying setting. All the actions are performed in six phases by the dryer itself without human intervention.

- 1 LOADING: the central and the loading auger start and the wet crop enters the dryer until the top level stops the loading process. The central auger continues moving.

- 2 FAN START AND DUST EXTRACTION: When the crop enters in the bin the fan and the cleaning process start automatically.

- 3 DRYING: once the top level has given consense to the burner, the drying process begins and goes on until the crop temperature has reached the programmed value.

- 4 COOLING: when the drying is over the cooling process immediately starts and stops when the target temperature or time is reached.

- 5 UNLOAD: when the crop is cooled down to the stocking temperature, the automatic unload starts.

- ∞ NEXT LOAD: When the dryer is empty the loading of the next batch starts automatically and the new wet crop enters the bin.